Fette Compacting

Capsule Filling

Machine

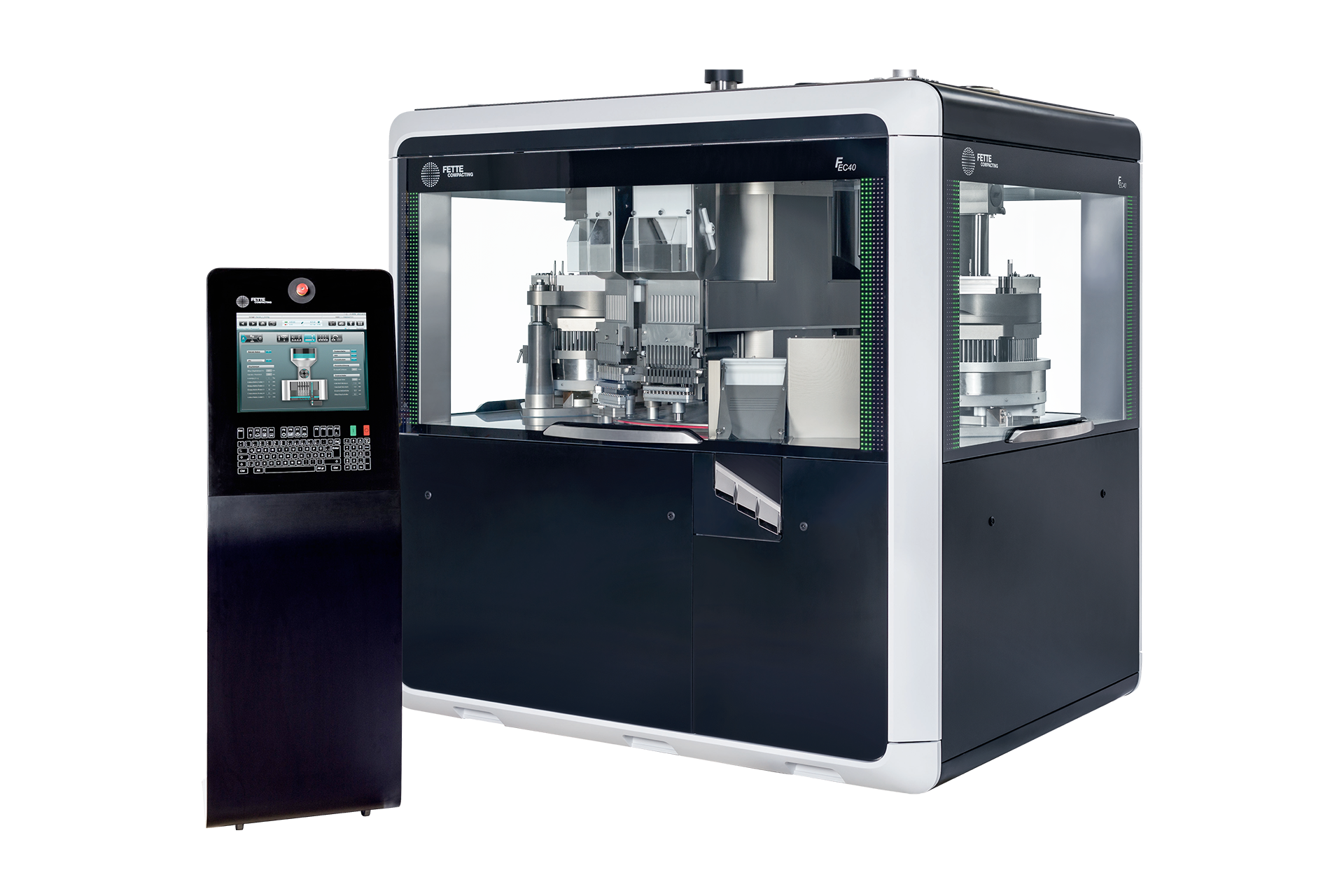

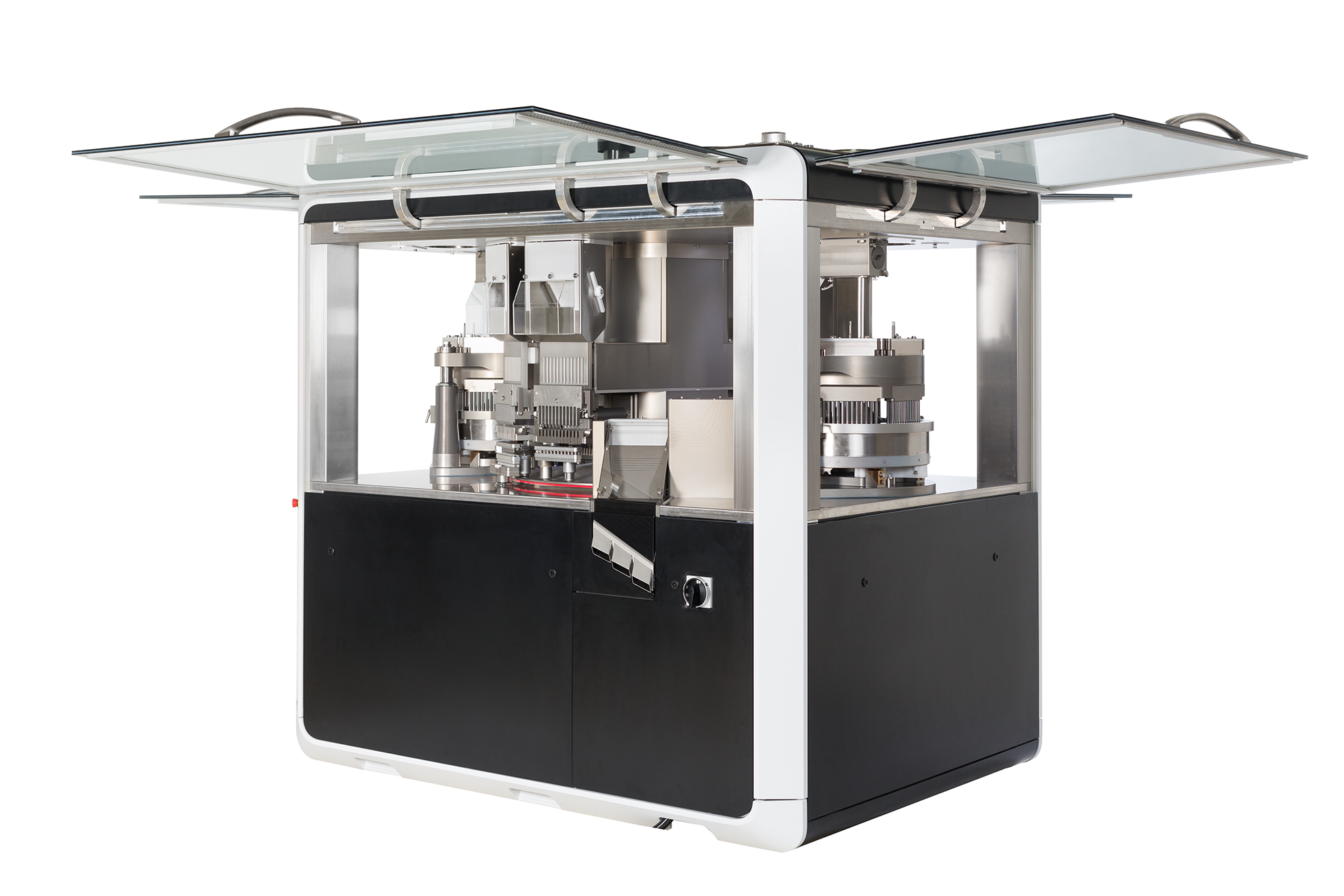

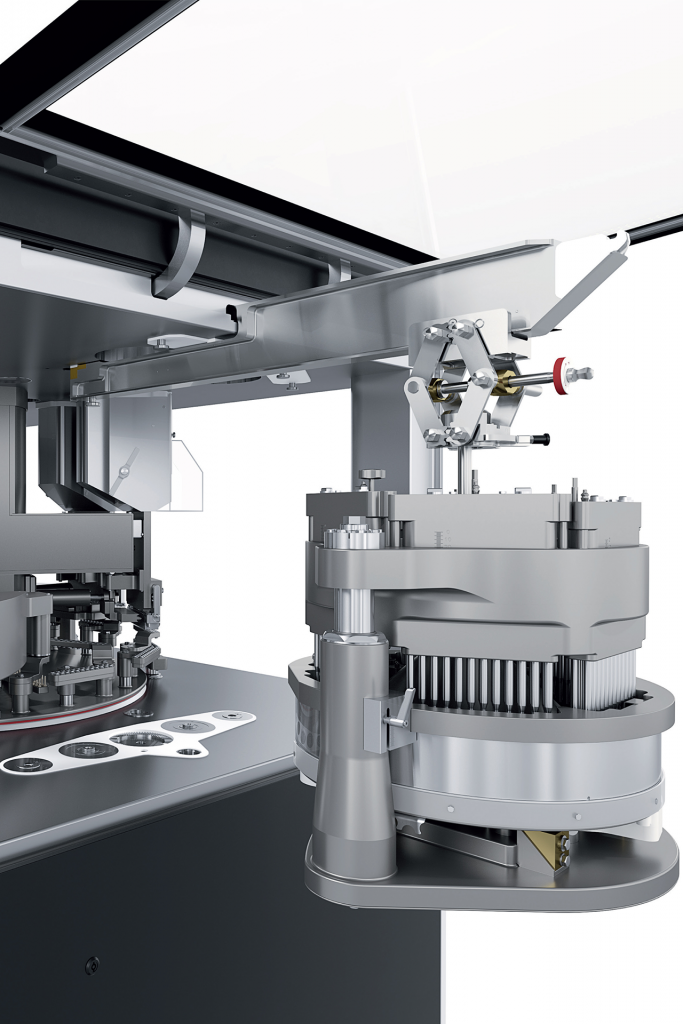

The subject of hygiene is the greatest challenge when it comes to designing the FEC40, the first capsule filling machine for the company Fette Compacting. The pharmaceutical industry requires meticulous care; that’s why a capsule filling machine must be completely disassembled for every new substrate. Only intensive cleaning can prevent powder traces from contaminating a subsequent product. So the design focuses on a comparatively simple cleaning process, thanks to the reduced number of components and gaps in the construction. At the same time, unlike other capsule filling machines made of stainless steel, we use components made of Corian composite material. This mineral-based material enables highly precise milling and almost invisible gluing.

The Studio F. A. Porsche is also responsible for designing the accompanying user interface. Their detailed understanding of the complex way a capsule filling machine works ensures a highly intuitive, user-friendly design for the terminal connected to the machine. The FEC40 is an innovation in the field of capsule filling. The first of its kind to produce up to 400,000 capsules per hour, it lowers production costs by 30%.